Key Design Principles

September 11, 2025 - Guilhem

What are the guiding principles behind ZAG’s design? In this new article, I’ll walk you through the technical choices that shape our cargo bike.

Contents :

A compact front-loader

A stiff, low frame

Chromoly steel

One-size frame

24’’ and 20’’ wheels

A durable bike

A Swiss-army-knife bike

A compact front-loader

As I mentioned in the first blog post, the starting idea was to create an electric touring bike capable of carrying weight (luggage and spare batteries) while still being fun to ride.

The cargo bike quickly emerged as a natural choice.

There are three main categories: the longtail, the low front-loading Bullitt-like bike, and the high front-loading Omnium-like bike. By “high,” I mean the cargo area sits above the front wheel. This raises the center of gravity but shortens the bike and its wheelbase – a key factor for playfulness. I quickly ruled out the longtail: during the many tests I did, I always preferred bikes loaded at the front. The choice of a high front-loader was confirmed after months of testing an Omnium, including on trips.

2. A stiff, low frame

Once the type of bike was decided, I asked myself what I wanted to do differently from the existing market. I had two main requirements: a short and stiff cargo bike.

A stiff frame means a bike that remains comfortable and precise to ride, even when fully loaded.

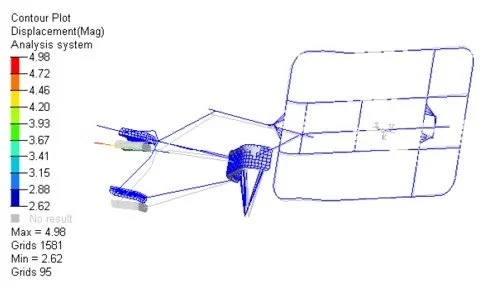

The first prototype didn’t meet expectations, so I spent long hours on modeling with the Antidote Solutions engineering office (thanks Ben!). This is where the “triangulation” of the front end was born, connecting the rack directly to the head tube to stiffen the whole assembly. On the second prototype, the difference in behavior under load was very noticeable.

This quest for stiffness also justified:

Reinforced tube sections.

No suspension – which also helps keep the cargo area as low as possible (for stability and ride comfort).

Overall, we get a stiff, strong, compact frame, naturally a bit heavier than if shedding grams had been the top priority. Still, the ZAG remains a relatively light cargo bike: 28.5–30 kg in electric version (depending on tires, kickstand, fenders) and about 6 kg lighter in a future non-electric version.

Finally, the sloping frame, directly inspired by MTB and dirt bikes, gives our cargo bike a unique silhouette while lowering the center of gravity and standover height.

3. Chromoly steel

I chose steel from the very beginning, mainly chromoly, a high-strength steel* commonly used in high-end steel bike frames.

Why?

Because I love the material: my first homemade MTB was a chromoly Sobre – and it’s still rolling 15 years later.

Because it’s easily repairable if needed.

Because it has a good carbon footprint (5-10 times better than aluminum per kg produced).

Because it allows for nice welds (TIG in our case).

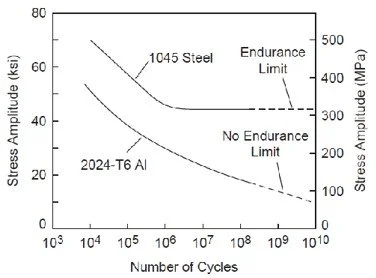

Because it’s resilient: unlike aluminum, steel has an endurance limit – the stress below which it will never fail, no matter how many cycles it undergoes.

4. One-size frame

This came up early in the design: should we make one size or multiple sizes? In the cargo bike world, both approaches exist, though one-size frames dominate. For example, the Omnium comes in five sizes, the Bullitt in one.

I’ve always preferred one size. First, I wanted a bike adaptable to riders through optimized frame geometry and peripheral components (stem, seatpost). Second, the original frame design doesn’t lend itself well to resizing. Finally, one size allows the same bike to be shared among family members or employees, and streamlines production.

These are the reasons why the ZAG frame is offered in a single size.

This choice required a few design specifics:

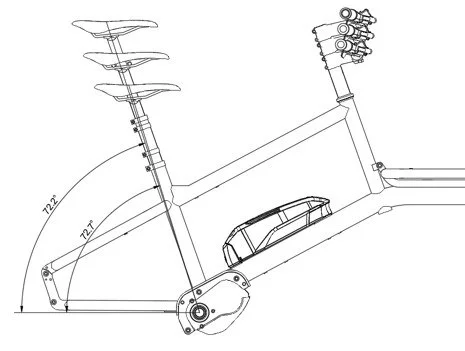

A relatively slack seat tube angle, to increase the setback of the saddle when raising it, compared to a conventional angle. However, the seat tube is also positioned forward relative to the bottom bracket, which maintains a virtual angle compatible with sporty or touring use (72–73°).

A two-piece (or telescopic) seatpost, allowing 50-85+ cm of saddle height, and compatibility with a suspension seatpost for any rider.

An adjustable cockpit: the Speedlifter offers 10 cm of height adjustment, and the stem comes in three lengths (70, 90, 110 mm) to fine-tune reach and stack.

The result? The bike fits riders from about 1.60 m to 1.95 m.

I’m 1.89 m tall and feel really comfortable on it, just like Sixtine at 1.72 m. Both of us have ridden our ZAG on trips with daily distances of 130 to 150 km, enjoying the same level of comfort. Testers over 1.90 m or under 1.60 m have tested it successfully. The best way to judge… is to try it!

5. 24’’ and 20’’ wheels

The 20” front wheel was obvious – it’s a well-established cargo bike standard and helps lower the cargo area.

At the rear, I first tested 27.5” and 26” wheels before settling on 24” for the second prototype and production. On a short bike, this visually complements well the 20” front wheel and lowers the center of gravity. It also provides 2 strong, rigid wheels, keeps the bike under 2 meters long while retaining a functional cargo area – and allows it to fit in an elevator, lobby, hotel room or train.

The frame and fork were also designed to accommodate tires up to 2.60” (65 mm), for comfort and grip on- and off-road.

The Mach 1 Trucky 35 rims (35 mm internal width) provide optimal support for wide tires, while accepting narrower tires (down to 2.15” / 55 mm).

6/ A durable bike

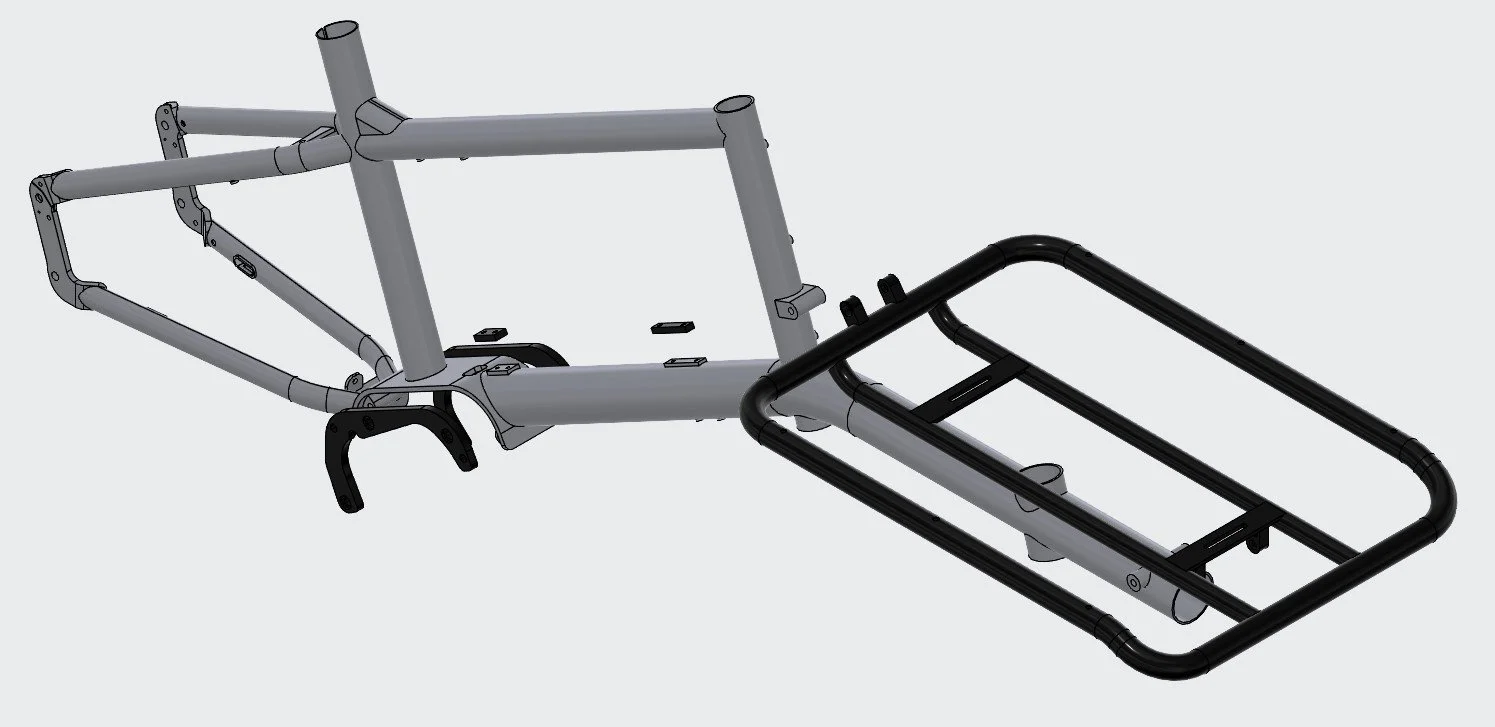

There is no standard frame mounting for mid-drive motors. They vary from one motor manufacturer to another (Shimano, Bosch, Yamaha, etc.) and sometimes even from one generation to the next within the same brand.

This is why another founding pillar of ZAG's design is its removable motor and battery mounting plates. These allow for a frame whose lifespan is no longer dictated by the availability of the motor or the battery.

In 10 years, the original EP801 motor will likely no longer be available – or even repairable. No problem: swapping the mounting plates will be all it takes to fit a new motor or battery. And if you ever want to ride the bike in a purely human-powered version, a simple adapter with a bottom bracket will make the conversion possible.

Durability also guided our choice of quality components and the electrophoretic coating ** of frames, forks, and racks before painting to ensure long-lasting corrosion resistance.

7/ A Swiss-army-knife bike

One bike for touring, another for evening rides, another for carrying kids, groceries, or professional gear.

I wanted a ZAG to do almost all :

It won’t go everywhere an MTB can – its favorite off-road playground is gravel, but with the front wheel offset, it feels to me more reassuring than a classic bike on steep descents.

It won’t replace a Bullitt X for hauling 300 liters upfront – but it can carry a 130-liter box or tow a Fleximodal or Carla Cargo trailer with up to 1,500 liters capacity.

It won’t carry 3 or 4 kids like some other cargo bikes – but you can mount a child seat on the front rack and another on the rear rack.

This versatility drove several choices: strong dropouts for a 40 kg rear rack or trailer hitch, kickstand mounts compatible with side/center stand, integrated lights usable without fenders, inserts for cargo cages or bottle cages under the top and down tube…

…and a compact but highly versatile front rack, designed to carry a box, a platform, a child seat, and, of course, a travel bag !

* The frame tubes are made of 25CrMo4 chromoly steel (also known as 4130 steel), a chromium-molybdenum alloy. It has a tensile strength of 750 MPa – three times that of standard steel, meaning it can handle 7.5 tons/cm² before breaking. Its yield strength (the maximum stress before permanent deformation) is around 600 MPa.

For sheets (motor mounts, dropouts, etc.), S 500 steel is used. Its composition differs slightly from chromoly, but its strength remains high (yield strength > 500 MPa).

** Electrophoretic coating (also known as cataphoresis) involves immersing a metal part in a bath so a thin protective layer coats all surfaces, inside and out. It’s a technique I discovered on my first Sobre frame (and kept in mind “for the day when…”).